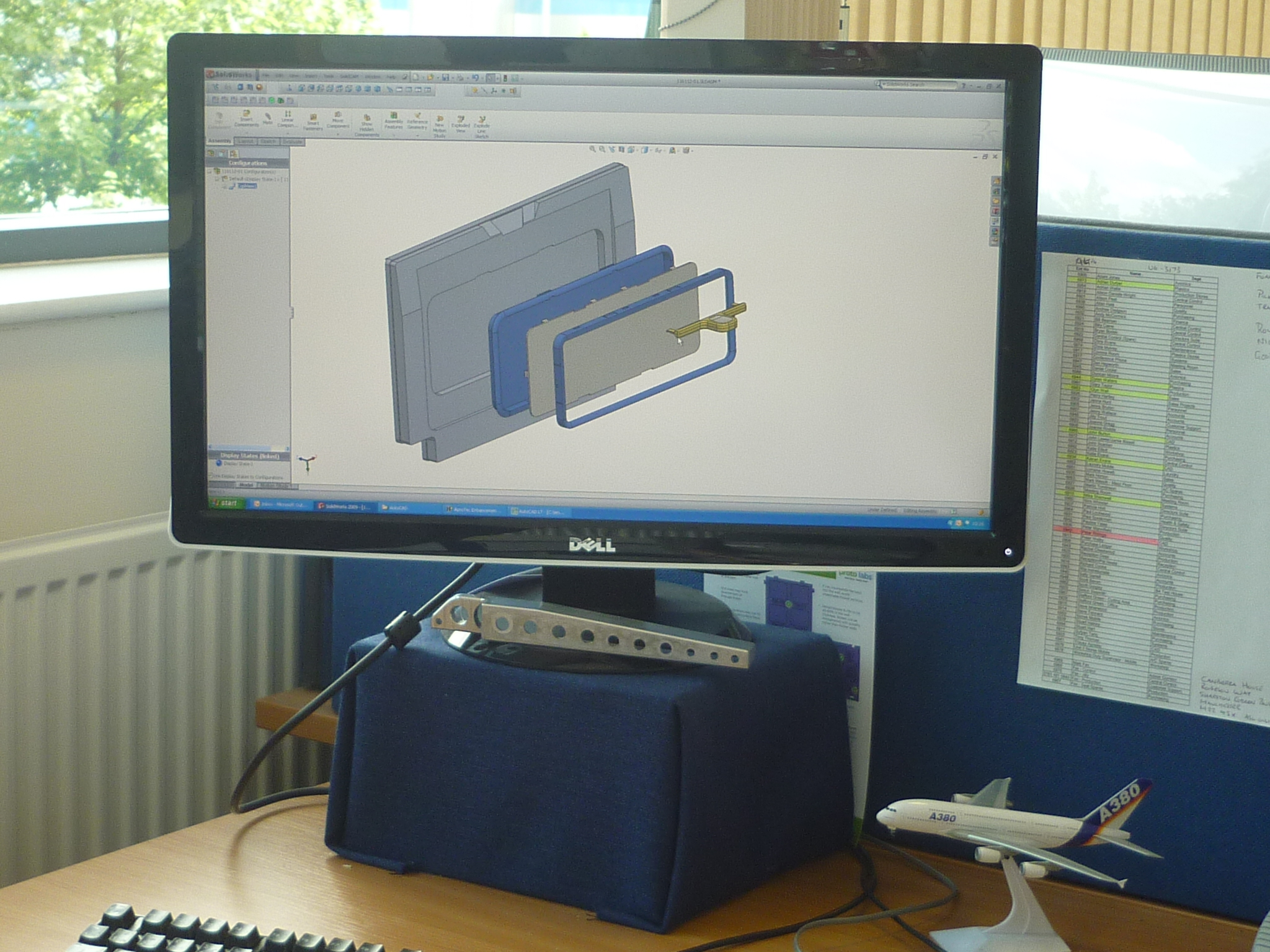

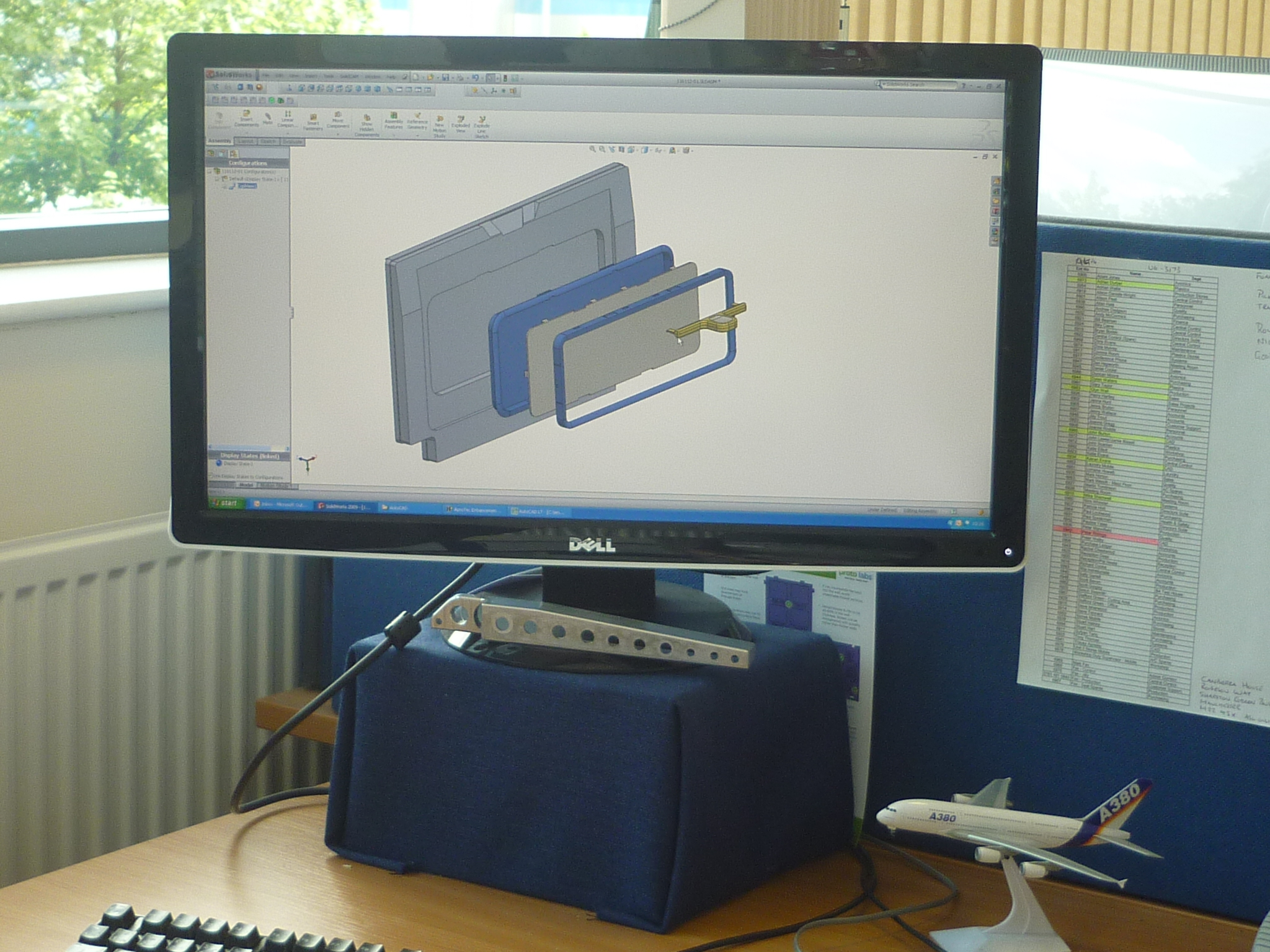

CAD Technology

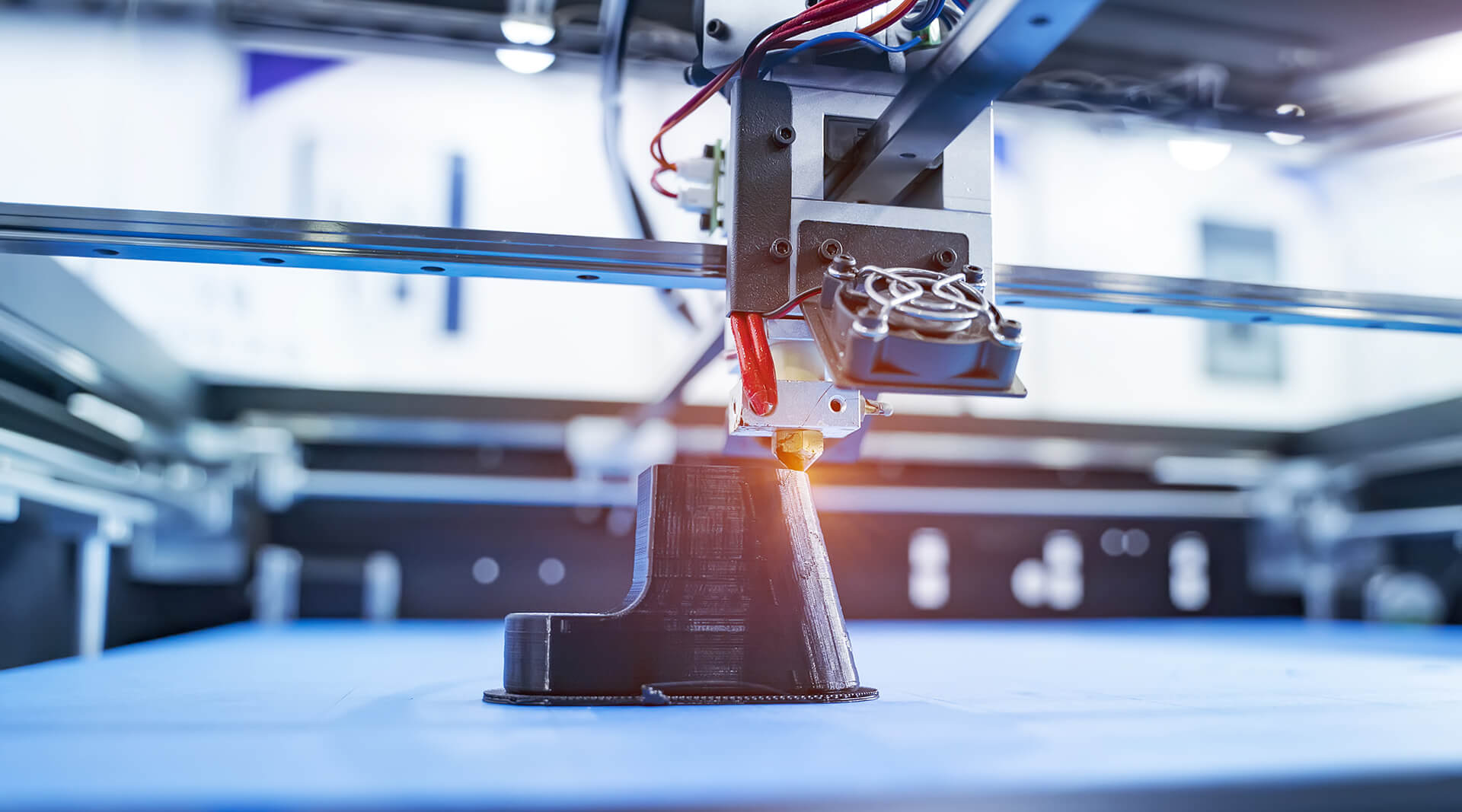

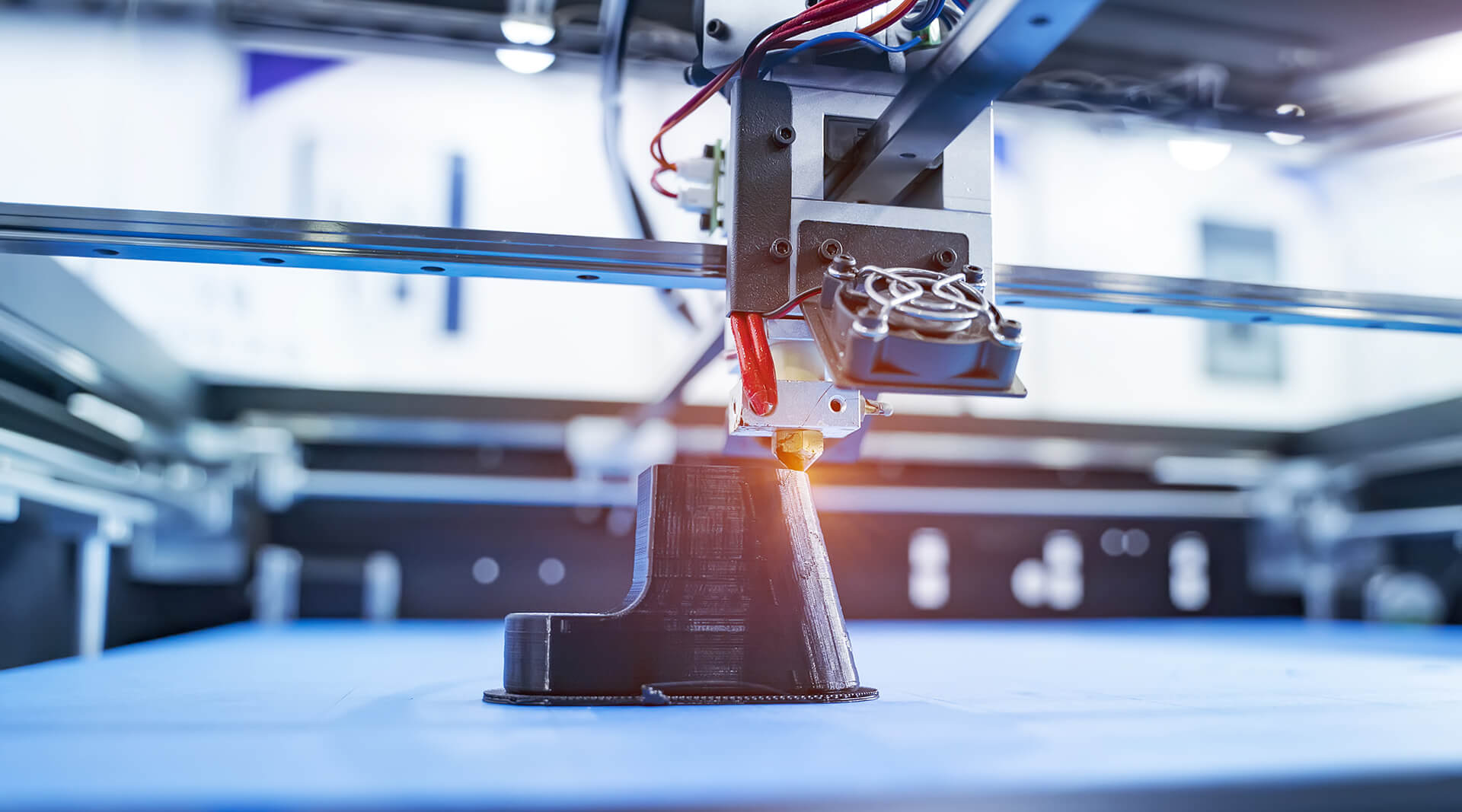

3D Printing

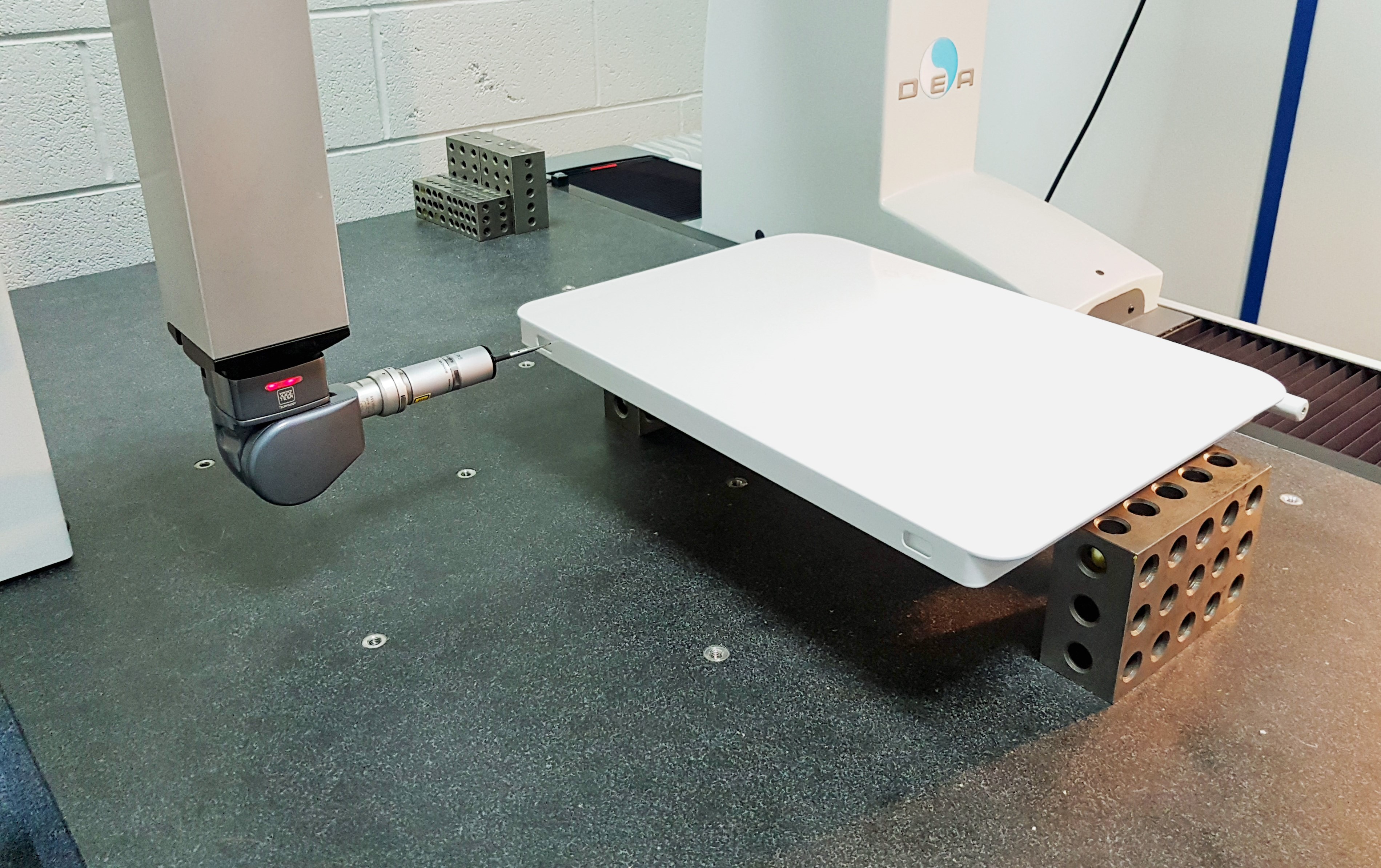

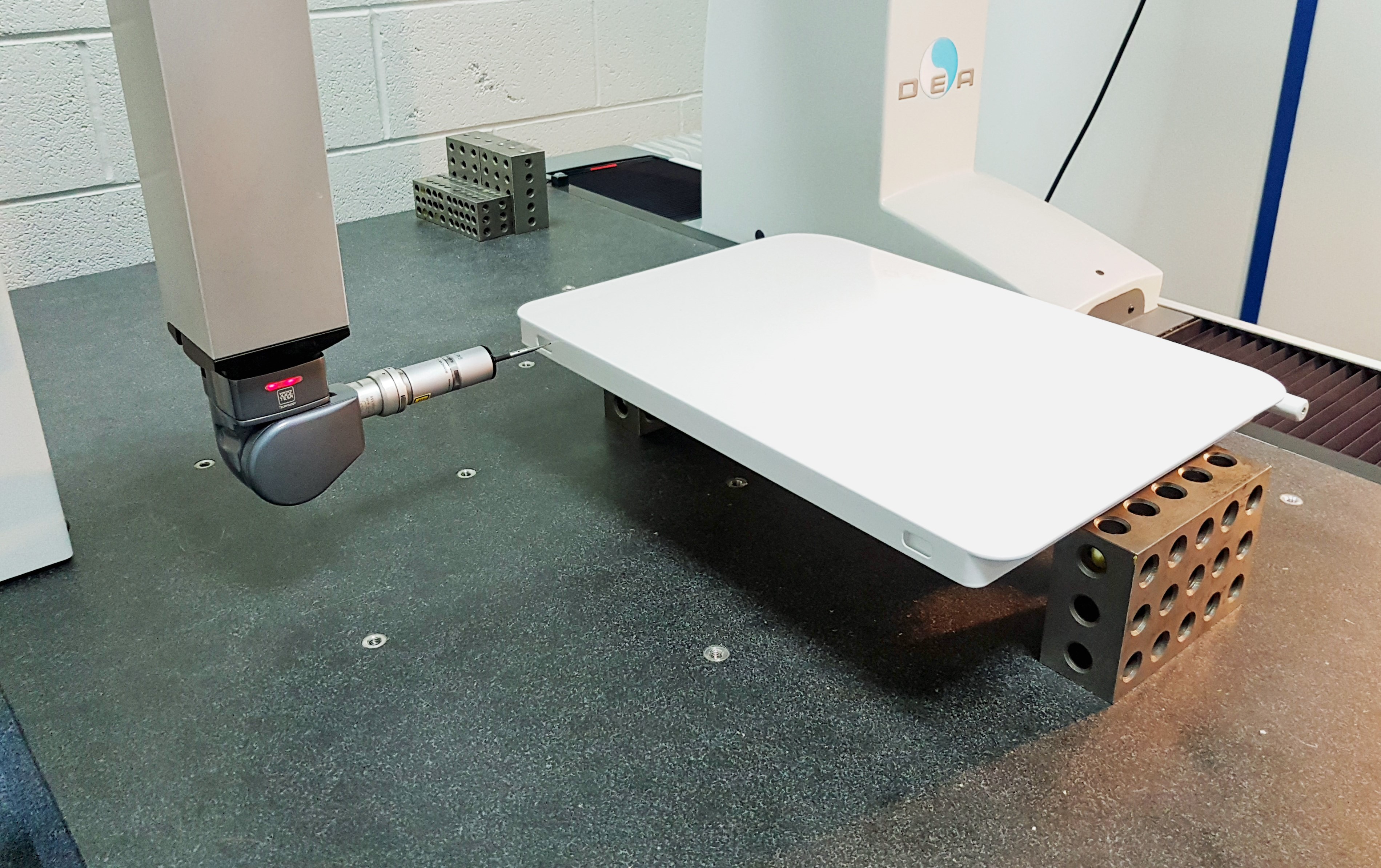

Coordinate Measuring Machine

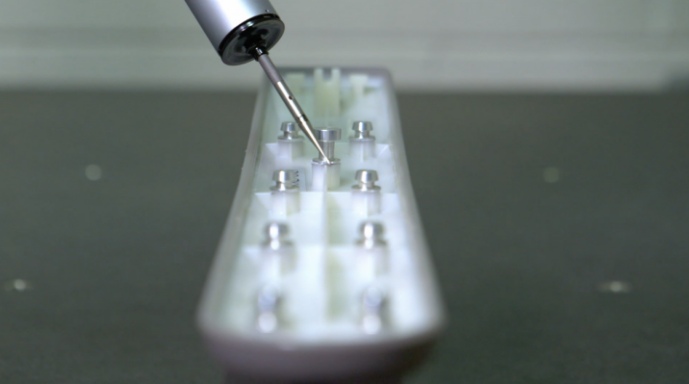

Row to Row HIC Testing

With our approvals and in-house capabilities we design, reverse engineer, test, manufacture and certify the installation of our supplied parts.

In-house flammability testing

Laser scanning for both in-house verification and on-wing surveys

3D Printing that can verify fit, form and function of components prior to tooling manufacture.

Tooling design and manufacture for both thermoformed and injection moulded parts.

Our in-house certification team provide design and certification activities in accordance with our UKCAA Part 21 Approval for the following:

- Aircraft Interior layout changes (LOPA)

- Carpet layouts

- Safety equipment layouts

- Retrofit on in-flight entertainment systems within the seats

- In-seat power solutions

- Seat cover changes in both fabric and leathers

- Reverse engineering of OEM seat parts

- Track mounted Monuments/Stowage's, Dogbox and Cabin Dividers

In support of these design activities, the certification team provide support with the verification and certification process. We prepare the modification package SB, ICA, W&B, test plans and test witnessing. If required we perform flammability testing at our in-house test lab and in conjunction with various external test facilities we perform static, abuse load, cyclic, delethalisation and or full dynamic testing to ensure compliance with the regulatory requirements.